Danfoss VLT FC 301 Drive Warnings-Alarms Part 1

Danfoss VLT FC 301/302 VFD Drive – Common Warnings⚠️and Alarms🚨 Explained Part-1

- Variable Frequency Drives (VFDs) play a crucial role in regulating motor speed and protecting equipment. The Danfoss VLT FC 301 is a widely used VFD in HVAC and industrial applications, offering advanced control, energy efficiency, and diagnostics.

- A Variable Frequency Drive (VFD) is an electronic device that regulates the speed and torque of an electric motor by changing the frequency and voltage supplied to it.

- It is widely used in industrial applications to control the speed of pumps, fans, conveyors, compressors, and other components, thereby saving energy and improving system performance.

- Variable Frequency Drives are critical for controlling motor speed and efficiency, but they can experience various faults during operation.

✅ Warning and Alarm Types:

- An alarm indicates a fault that requires immediate attention.

- The fault always triggers a trip or trip lock.

- Press [Reset] or [Off & Reset],

- Digital reset input command,

- Serial communication reset input command.

- Auto reset.

- A state entered in fault situations, for example if the drive is subject to an overtemperature or when the drive is protecting the motor, process, or mechanism.

- The drive prevents a restart until the cause of the fault has disappeared.

- To cancel the trip state, restart the drive.

- Do not use the trip state for personal safety.

- Trip When tripping, the drive suspends operation to prevent damage to the drive and other equipment.

- When a trip occurs, the motor coasts to a stop.

- The drive logic continues to operate and monitor the drive status.

- After the fault condition is remedied, the drive is ready for a reset.

✔️Trip lock:

- The drive enters this state in fault situations to protect itself.

- The drive requires physical intervention, for example when there is a short circuit on the output.

- A trip lock can only be cancelled by disconnecting mains, removing the cause of the fault, and reconnecting the drive.

- Restart is prevented until the trip state is cancelled by activating reset or, sometimes, by being programmed to reset automatically.

- Do not use the trip lock state for personal safety.

✔️ LCP notification:

When a fault is triggered, the LCP indicates the type of fault (alarm, warning, or trip lock) and shows the alarm or warning number in the display.

These faults can typically be categorized into electrical, mechanical, and operational issues.

Here are the most common faults in VFDs:

WARNING: 1 (10-Volts low)

Cause:

- The control card voltage is less than 10 Volt from terminal 50.

- Remove some of the load from terminal 50, as the 10 Volt supply is overloaded.

- Maximum 15 mA or minimum 590 ohm.

- A short circuit in a connected potentiometer or incorrect wiring of the potentiometer can cause this condition.

- Remove the wiring from terminal 50,

- If the warning clears, the problem is with the wiring,

- If the warning does not clear, replace the control card.

WARNING/ALARM: 2 (Live zero error)

Cause:

- This warning or alarm only appears if programmed by the user in parameter 6-01 Live Zero Timeout Function.

- The signal on 1 of the analog inputs is less than 50% of the minimum value programmed for that input.

- Broken wiring or faulty device sending the signal can cause this condition.

Troubleshooting Methods:

- Check connections on all the analog input terminals,

- Control card terminals 53 and 54 for signals, terminal 55 common,

- VLT General Purpose I/O MCB 101 terminals 11 and 12 for signals, terminal 10 common,

- VLT Analog I/O MCB 109 terminals 1, 3, 5 for signals, terminals 2, 4, 6 common,

- Check that the frequency converter programming and switch settings match the analog signal type,

- Perform Input Terminal Signal Test,

WARNING/ALARM: 3 (No motor)

Cause:

- No motor is connected to the output of the frequency converter.

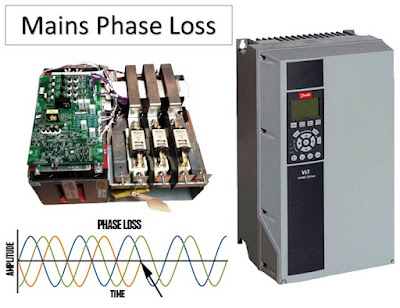

WARNING/ALARM: 4 (Mains Phase Loss)

Cause:

- A phase is missing on the supply side, or the mains voltage imbalance is too high.

- This message also appears for a fault in the input rectifier.

- Options are programmed in parameter 14-12 Response to Mains Imbalance.

Troubleshooting Methods:

- Check the supply voltage and supply currents to the frequency converter.

WARNING: 5 (DC link Voltage High)

Cause:

- The DC-link voltage is higher than the high-voltage warning limit.

- The limit depends on the frequency converter voltage rating.

- The unit is still active.

WARNING: 6 (DC Link Voltage Low)

Cause:

- The DC-link voltage is lower than the low-voltage warning limit.

- The limit depends on the frequency converter voltage rating.

- The unit is still active.

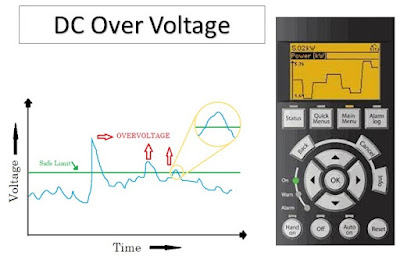

WARNING/ALARM: 7 (DC Over Voltage)

Cause:

- If the DC-link voltage exceeds the limit, the frequency converter trips after some time.

Troubleshooting Methods:

- Connect a brake resistor.

- Extend the ramp time.

- Change the ramp type.

- Activate the functions in parameter 2-10 Brake Function.

- Increase parameter 14-26 Trip Delay at Inverter Fault.

WARNING/ALARM: 8 (DC Under Voltage)

Cause:

- If the DC-link voltage drops below the under voltage limit, the frequency converter checks if a 24 Volt DC back-up supply is connected.

- If no 24 Volt DC back-up supply is connected, the frequency converter trips after a fixed time delay.

- The time delay varies with unit size.

Troubleshooting Methods:

- Check that the supply voltage matches the frequency converter voltage.

- Perform an input voltage test.

- Perform a soft charge circuit test.

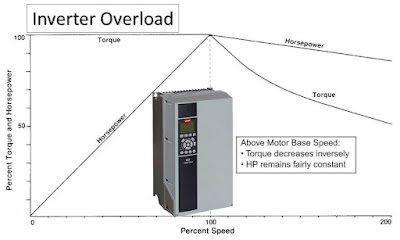

WARNING/ALARM: 9 (Inverter Overload)

Cause:

- The frequency converter has run with more than 100% overload for too long and is about to cut out.

- The counter for electronic thermal inverter protection issues a warning at 98% and trips at 100% with an alarm.

- The frequency converter cannot be reset until the counter is below 90%.

Troubleshooting Methods:

- Compare the output current shown on the LCP with the frequency converter rated current and measured motor current

- Show the thermal frequency converter load on the LCP and monitor the value.

- When running above the frequency converter continuous current rating, the counter increases.

- When running below the frequency converter continuous current rating, the counter decreases.

WARNING/ALARM: 10 (Motor Overload Temperature)

Cause:

- According to the electronic thermal protection (ETR), the motor is too hot.

Select 1 of these options:

- The frequency converter issues a warning or an alarm when the counter is >90% if parameter 1-90 Motor Thermal Protection is set to warning options.

- The frequency converter trips when the counter reaches 100% if parameter 1-90 Motor Thermal Protection is set to trip options.

- The fault occurs when the motor runs with more than 100% overload for too long.

Troubleshooting Methods:

- Check for motor overheating.

- Check if the motor is mechanically overloaded.

- Check that the motor current set in parameter 1-24 Motor Current is correct.

- Ensure that the motor data in parameters 1-20 to 1-25 is set correctly.

- If an external fan is in use, check that it is selected in parameter 1-91 Motor External Fan.

- Running AMA in parameter 1-29 Automatic Motor Adaptation (AMA) tunes the frequency converter to the motor more accurately and reduces thermal loading.

✅ SAFETY PRECAUTION IN VFD TROUBLESHOOTING:

- Troubleshooting a Variable Frequency Drive (VFD) involves working with high voltages, currents, and sensitive electronic components.

- Adhering to safety precautions is essential to protect personnel and equipment.

Here are the key safety measures to follow:

- Ensure Proper Isolation,

- Use Personal Protective Equipment (PPE),

- Avoid Direct Contact with Live Circuits,

- Follow Manufacturer's Guidelines,

- Work in a Safe Environment,

- Monitor Static Electricity,

- Check for Stored Energy,

- Use the Right Diagnostic Tools,

- Be Mindful of Rotating Parts,

- Never Bypass Safety Features,

- Avoid Overloading Knowledge,

- Document the Process,

By following these procedures, you can secure your own and others' safety while maintaining the VFD system's reliability.

✅ Conclusion:

➤ Understanding the warning and alarm codes of the Danfoss VLT FC 301 VFD is essential for timely troubleshooting and maintaining system uptime ⚙️🔄

➤ In this first part, we’ve covered some of the most frequently encountered warnings each offering valuable insights into the drive’s status and performance.🛠️

➤ Stay tuned for Part 2, where we’ll explore additional alarms and advanced fault diagnostics to help you keep your drives running smoothly.

➤ For best practices, always refer to the official Danfoss user manual 📘 and follow safety procedures when performing any maintenance.

Video Link:

🔗 Connect with Me:

╰┈➤YouTube

╰┈➤Tumblr

╰┈➤Slide share

╰┈➤Quora

I hope you learnt something from this article📖

Please provide feedback on this article; this will help me improve my feature Blog Post 📝

Come look around, leave a comment, and contact us; I always like hearing from you🎯

Have a wonderful day❤️

Thank you for visiting🙏

Comments

Post a Comment